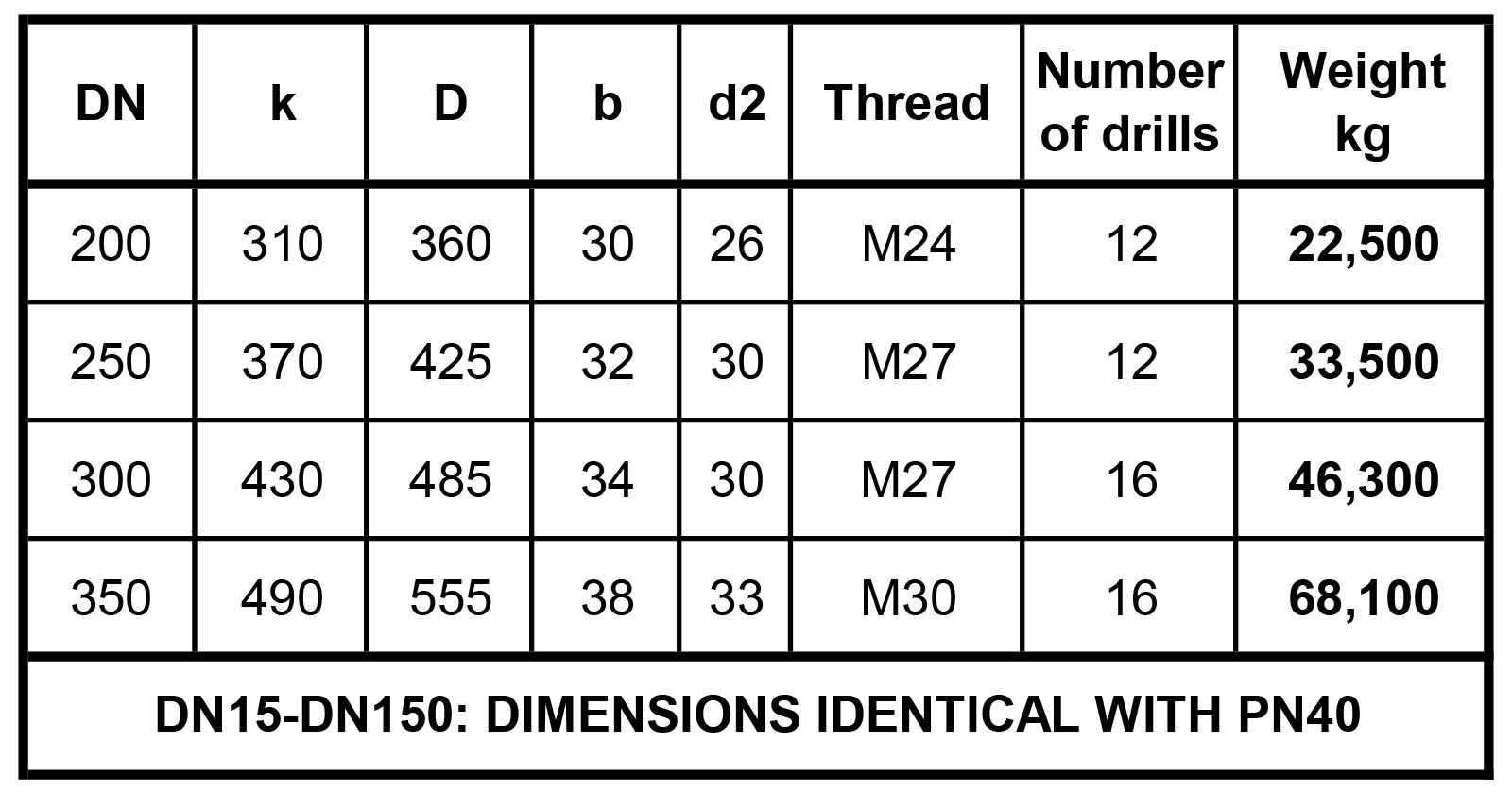

| DIMENSION | SIZE | TOLERANCES |

|---|---|---|

|

D Outside diameter |

≤ DN 200 | ± 1,0 |

| > DN 200 ≤ DN 300 | ± 1,5 | |

| > DN 300 ≤ DN 400 | ± 2,0 | |

| > DN 400 | ± 2,0 | |

|

d1 Outside diameter of neck |

≤ DN 100 | +0,5 -0 |

| > DN 100 ≤ DN 400 | +1,0 -0,5 | |

| > DN 400 | +1,5 -1,0 | |

|

d1 Bore diameter |

≤ DN 80 | +0,5 -0 |

| > DN 80 ≤ DN 350 | +1,0 -0 | |

| > DN 350 ≤ DN 400 | +1,5 -0 | |

| > DN 400 | +5 | |

|

b Thickness |

≤ DN 10 | ± 0,5 |

| > DN 10 ≤ DN 20 | ± 0,8 | |

| > DN 20 ≤ DN 50 | ± 1,0 | |

| > DN 50 | ± 1,5 | |

|

d3 Neck diameter |

+1 -0 | |

|

h1 Length through hub |

≤ DN 80 | ± 1,5 |

| > DN 80 ≤ DN 250 | ± 2,0 | |

| > DN 250 | ± 3,0 | |

|

S Wall thickness |

≤ DN 100 | +1,0 -0 |

| > DN 100 ≤ DN 400 | +1,5 -0 | |

| > DN 400 | +2,0 -0 | |

|

d4 Diameter of contact face |

≤ DN 80 | +0 -1,0 |

| > DN 100 ≤ DN 400 | +0 -2,0 | |

| > DN 400 | +0 -3,0 | |

|

k Diameter of bolt circle |

≤ DN 250 | ± 1,5 |

| > DN 250 ≤ DN 600 | ± 2,0 | |

| > DN 600 | ± 3,0 | |

| Centre-to-centre of adjacent bolt holes | ± 0,4 | |

| Max. eccentricity between bolt circle dia. K and machined facing diameters | +0,8 -0 | |

| Surface parallelism | 1° | |

|

d2 Holes diameter |

≤ DN 300 | +2 -0 |

| > DN 30 | +3 -0 |

| D | Outside Diameter* | Slip-on, Blind and Welding neck flanges | When OD is 24" or less | ±1,6 mm |

| When OD is over 24" | ±3,2 mm | |||

| J | Inside Diameter | Slip-on flanges | 10" and smaller | +0,8 mm |

| 12" and larger | +1,6 mm | |||

| Inside Diameter** | Welding neck flanges | 10" and smaller | +0,8 mm | |

| 12" to 18" | +1,6 mm | |||

| 20" and larger | +3,2 mm -1,6 mm | |||

| g | Diameter of Contact Face | Slip-on, Blind and Welding neck flanges | 1,6 mm Raised Face | ±0,8 mm |

| 6,4 mm Raised Face | ±0,5 mm | |||

| a | Diameter of Hub at Point of Welding | Welding neck flanges | 5" and smaller | +2,4 mm -0,8 mm |

| 6" and larger | +4,0 mm -0,8 mm | |||

| m | Outside Diameter of Hub* | Slip-on and Blind flanges | 12" and smaller | +2,4 mm -1,6 mm |

| 14" and larger | ±3,2 mm | |||

| Diameter of Hub at Base* | Welding neck flanges | When Hub Base is 24" or less | ±1,6 mm | |

| When Hub Base is over 24" | ±3,2 mm | |||

| i | Drilling and facing | Slip-on, Blind and Welding neck flanges | Bolt Circle Diameter k | 1,6 mm |

| Center-to-center of adjacent bolt holes | ±0,8 mm | |||

| mmMax. eccentricity between bolt circle dia. kand machined facing diameters | ||||

| sizes 2½" and smaller | 0,8 mm | |||

| sizes 3" and larger | 1,6 mm | |||

| h | Overall Length of Hub | Slip-on and Blind flanges | 18" and smaller | +3,2 mm -0,8 mm |

| 20" and larger | +4,8 mm -1,6 mm | |||

| Welding neck flanges | 10" and smaller | ±1,6 mm | ||

| 12" and larger | ±3,2 mm | |||

| b | Thickness | Slip-on, Blind and Welding neck flanges | 18" and smaller | +3,2 mm |

| 20" and larger | +4,8 mm |

* This tolerance is not covered by ANSI B 16.5

** Undependent of the tolerances of the measures J and a, the wall thickness shall not be less than 87,5% of the nominal wall thickness

| Dimension | Flange type | Size | Tolerance mm |

|---|---|---|---|

| Outside diameter of neck d1 | 11 | ≤DN 125 | 0 to +3,0 |

| >DN 125 ≤ DN 1200 | 0 to +4,5 | ||

| >DN 1200 | 0 to +6,0 | ||

|

Bore diameter d1 |

01, 02 | ≤DN 100 | 0 to +0,5 |

| >DN 100 ≤ DN 400 | 0 to +1,0 | ||

| >DN 400 ≤ DN 600 | 0 to +1,5 | ||

| >DN 600 | 0 to +3,0 | ||

| Wall thickness S | 11 |

Machined neck

machined or

(both faces)

Neck one face

machined or

unmachined

|

|

| ≤DN 100 |

0 to +1,0

0 to +2,0

|

||

| ≤DN 100 |

0 to +1,5

0 to +2,5

|

||

| ≤DN 100 |

0 to +2,0

0 to +3,5

|

||

|

Outside diameter D |

01, 02, 05, 11, 13 | ≤DN 150 | ±2,0 |

| >DN 150 ≤ DN 500 | ±3,0 | ||

| >DN 500 ≤ DN 1200 | ±5,0 | ||

| >DN 1200 ≤ DN 1800 | ±7,0 | ||

| >DN 1800 | ±10,0 | ||

|

Length through hub h1 |

11 | ≤DN 80 | ±1,5 |

| >DN 80 ≤ DN 250 | ±2,0 | ||

| >DN 250 | ±3,0 | ||

|

Neck diameter d3 |

11 | ≤DN 50 | 0 to -2,0 |

| >DN 50 ≤ DN 150 | 0 to -4,0 | ||

| >DN 150 ≤ DN 300 | 0 to -6,0 | ||

| >DN 300 ≤ DN 600 | 0 to -8,0 | ||

| >DN 600 ≤ DN 4000 | 0 to -10,0 | ||

|

Neck diameter d3 |

13 | ≤DN 50 | 0 to +1,0 |

| >DN 50 ≤ DN 150 | 0 to +2,0 | ||

| >DN 150 ≤ DN 300 | 0 to +4,0 | ||

| >DN 300 ≤ DN 600 | 0 to +8,0 | ||

| >DN 600 ≤ DN 1200 | 0 to +12,0 | ||

| >DN 1200 ≤ DN 1800 | 0 to +16,0 | ||

| >DN 1800 | 0 to +20,0 | ||

|

Flange thickness b |

All types (machined on both faces) | ≤18 mm thickness | -1,3 to +1,0 |

| >18mm ≤50mm thickness | ±1,5 | ||

| > 50 mm thickness | ±2,0 | ||

|

Flange thickness b |

All types (machined on front face only) Type 02 and 04 (un- machined) | ≤18 mm thickness | -1,3 to +2,0 |

| >18mm ≤50mm thickness | -1,5 to +4,0 | ||

| > 50 mm thickness | -2,0 to +7,0 | ||

|

Diameter of bolt circle K |

01, 02, 05, 11, 13 | Bolt sizes M10 to M24 | ±1,0 |

| Bolt sizes M27 to M45 | ±1,5 | ||

|

Center-to-center of adjacent bolt holes |

01, 02, 05, 11, 13 | Bolt sizes M10 to M24 | ±1,0 |

| Bolt sizes M27 to M45 | ±1,5 | ||

|

Eccentricity of machined facing diameters |

01, 02, 05, 11, 13 | ≤ DN 65 | 1,0 |

| > DN 65 | 2,0 |

| Type 01 - Plate Flanges | Type 02 - Plate Flanges | Type 05 - Plate Flanges | Type 11 - Plate Flanges | Type 13 - Threaded Flanges |